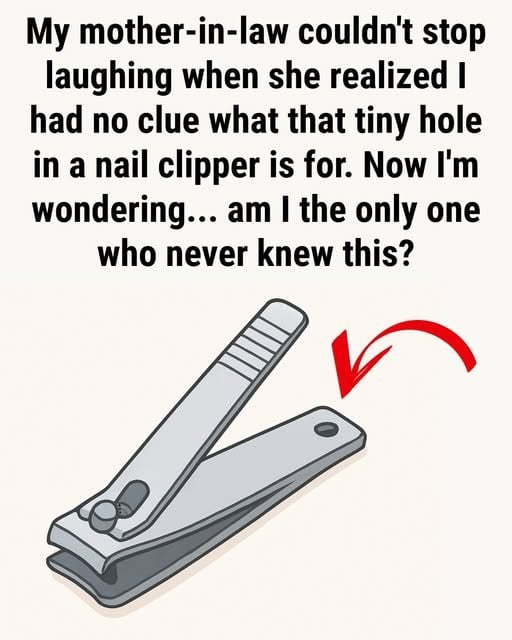

Many people have noticed the small circular dent on plastic milk jugs without understanding its purpose. Though it appears to be a simple design detail, this indentation serves an important function that manufacturers include intentionally.

The dent helps make the jug safer, stronger, and more reliable during everyday use. Its primary purpose involves pressure control as milk containers experience temperature changes throughout their journey from delivery trucks to store shelves and home refrigerators.

When liquids warm or cool, they naturally expand or contract. The circular indentation provides flexible area that can shift slightly to accommodate these volume changes, protecting the jug from unwanted stress or structural damage.

The dent also reinforces the jug’s overall structure through effective force distribution. Rounded shapes naturally disperse pressure, making the container sturdier without requiring thicker plastic. This added durability helps prevent cracking or leaking during transport, stocking, or accidental bumps at home.

Occasionally, the dent may appear pushed slightly outward or inward due to normal handling or temperature shifts. This movement simply demonstrates how the design flexes when needed, adapting to everyday conditions.

This clever engineering solution creates a stronger container without adding extra weight or manufacturing cost. It represents thoughtful design that balances functionality with practicality.

Along with features like the handle cutout and base ridges, the circular dent reveals how much careful engineering goes into products we use daily. What seems ordinary often contains hidden intelligence waiting to be noticed.